Direct-to-Film (DTF) technology offers high-quality, durable prints on flexible materials, eliminating the need for traditional printing plates. Ideal for short runs and last-minute changes, DTF involves applying ink to film and curing it permanently, resulting in vibrant, outdoor-durable prints suitable for displays, labels, and events. As a game-changer for marketing, DTF provides custom visuals tailored for various business applications, from retail signage to exhibitions. Choosing the right DTF materials and equipment ensures top-quality prints, with advancements in materials and automation promising even greater efficiency and visual impact in the future.

In today’s visual-centric business landscape, high-quality direct-to-film (DTF) transfers have emerged as a game-changer for various industries. This article delves into the world of commercial-grade DTF transfers, offering a comprehensive guide for businesses seeking innovative ways to enhance their marketing and branding strategies. From understanding the fundamentals of DTF printing to exploring real-world applications, we’ll uncover how this technology is revolutionizing visual communication. Get ready to explore the future of DTF prints and unlock your brand’s full potential.

- Understanding Direct-to-Film (DTF) Transfers: A Comprehensive Overview

- Benefits of Commercial-Grade DTF for Business Applications

- The Process: From Design to Final DTF Prints

- Choosing the Right Materials and Equipment for Optimal Results

- Real-World Use Cases: Success Stories from Various Industries

- Future Trends in DTF Printing for Businesses

Understanding Direct-to-Film (DTF) Transfers: A Comprehensive Overview

Direct-to-Film (DTF) Transfers are a cutting-edge printing technology revolutionizing various business applications. This innovative process allows for high-quality, durable prints directly onto film and other flexible materials, opening up a world of possibilities for branding, packaging, and promotional items. Unlike traditional printing methods that rely on physical plates or screens, DTF transfers use a digital approach, enabling precise and vibrant prints with exceptional detail.

DTF Printing offers several advantages, particularly in terms of efficiency and versatility. It eliminates the need for intricate set-up and plate preparation, making it ideal for short-run productions and last-minute changes. The process involves applying a thin layer of ink to the film surface, followed by heating or curing to fix the image permanently. This method produces crisp, full-color DTF prints that are resistant to fading and ideal for outdoor displays, product labels, and event signage. With its ability to create custom, high-impact visuals, DTF Transfer is a game-changer for businesses seeking effective marketing solutions.

Benefits of Commercial-Grade DTF for Business Applications

Commercial-grade direct-to-film (DTF) transfers offer a multitude of benefits for business applications. Firstly, they enable high-quality printing on various substrates, from vinyl banners to window graphics, ensuring vibrant and durable DTF prints that can withstand outdoor conditions. This versatility allows businesses to create eye-catching signage, branding materials, and promotional items with consistent visual appeal.

Moreover, DTF Transfer technology streamlines production processes, enhancing efficiency and reducing costs. By eliminating the need for intricate cutting and weeding, businesses can save time and labour expenses. The precision of DTF printing ensures clean, crisp lines and accurate colour reproduction, resulting in professional-looking final products. This level of quality and consistency is particularly valuable for businesses seeking to maintain a strong brand image across their marketing collateral.

The Process: From Design to Final DTF Prints

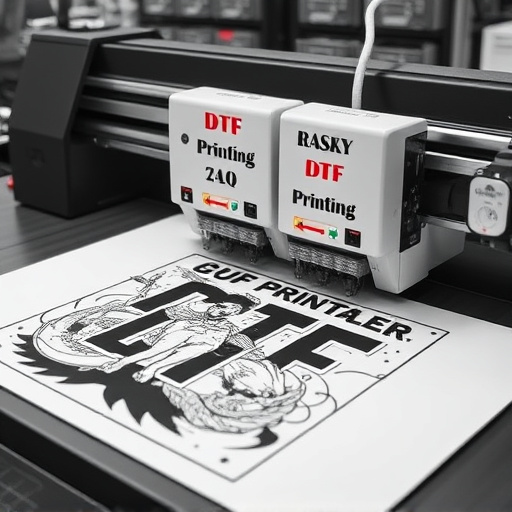

The process of creating commercial-grade direct-to-film (DTF) transfers involves a meticulous journey from design to final DTF prints. It all begins with the art or design, which is digitally prepared and optimized for printing. This step ensures the artwork meets specific resolution and color profile requirements for accurate reproduction on the desired surface. Once ready, the design is carefully loaded onto the DTF printer, a specialized machine designed to apply the image directly onto various materials.

During printing, the DTF transfer material, often a thin film coated with a water-soluble adhesive, is precisely positioned over the substrate—be it vinyl, fabric, or other media. The printer then uses ultra-high-resolution technology to transfer the design with pinpoint accuracy. After printing, the excess DTF material is carefully removed, leaving behind a crisp, clear image bonded to the substrate. This involves careful trimming and finishing to ensure the final DTF prints meet industry standards for quality and durability.

Choosing the Right Materials and Equipment for Optimal Results

When it comes to commercial-grade direct-to-film (DTF) transfers, selecting the right materials and equipment is paramount for achieving optimal results. The quality of DTF films and inks plays a significant role in ensuring crisp, vibrant prints that meet business requirements. Opting for high-resolution DTF films capable of handling intricate designs and fine details is essential. Moreover, choosing durable, long-lasting inks resistant to fading and smudging guarantees that DTF prints remain visually appealing for extended periods.

Equally important is investing in reliable DTF printing equipment that aligns with your application needs. From flatbed printers to specialized DTF presses, the right machinery should offer precision control over print quality, speed, and consistency. Maintaining regular calibration and upkeep of these devices ensures accurate color reproduction and minimizes waste, ultimately enhancing productivity and efficiency in business operations that rely on direct-to-film transfers.

Real-World Use Cases: Success Stories from Various Industries

Commercial-grade direct-to-film (DTF) transfers have proven their mettle across diverse industries, offering unparalleled quality and efficiency in various real-world applications. From retail signage and pop-up stores to event branding and temporary exhibition displays, DTF Transfer has become a game-changer for businesses seeking dynamic, eye-catching visuals without the usual constraints of traditional printing methods.

In the retail sector, for instance, DTF Printing enables retailers to create captivating in-store displays, window graphics, and promotional materials that capture customers’ attention and drive sales. Similarly, event organizers benefit from the speed and versatility of DTF Transfers, allowing them to craft distinctive branding elements for conferences, trade shows, and festivals, enhancing the overall attendee experience. Moreover, temporary exhibition spaces have embraced DTF, producing high-resolution prints on demand for informational panels, product displays, and art installations, making it an ideal solution for flexible, cost-effective visuals in ever-changing environments.

Future Trends in DTF Printing for Businesses

The future of direct-to-film (DTF) transfers for business applications is looking bright and innovative. As technology continues to advance, we can expect to see several exciting trends emerging in DTF printing. One notable trend is the integration of advanced materials that offer higher resolution and more vibrant colors, enabling businesses to create visually stunning prints with intricate details. This advancement will be particularly beneficial for marketing materials, branded merchandise, and visual displays.

Additionally, the automation of DTF printing processes is on the rise, promising increased efficiency and reduced production times. Automated systems can streamline large-scale print jobs, making them more cost-effective for businesses. With the introduction of smart printers equipped with AI capabilities, DTF prints can be tailored to individual customer preferences, ensuring a personalized experience without compromising quality. These future trends suggest that DTF transfers will play an even more significant role in enhancing brand visibility and engaging customers through dynamic visual solutions.